China 6 Axis 1800mm Arm ukufikelela Steel MIG Welding Robotic Arm

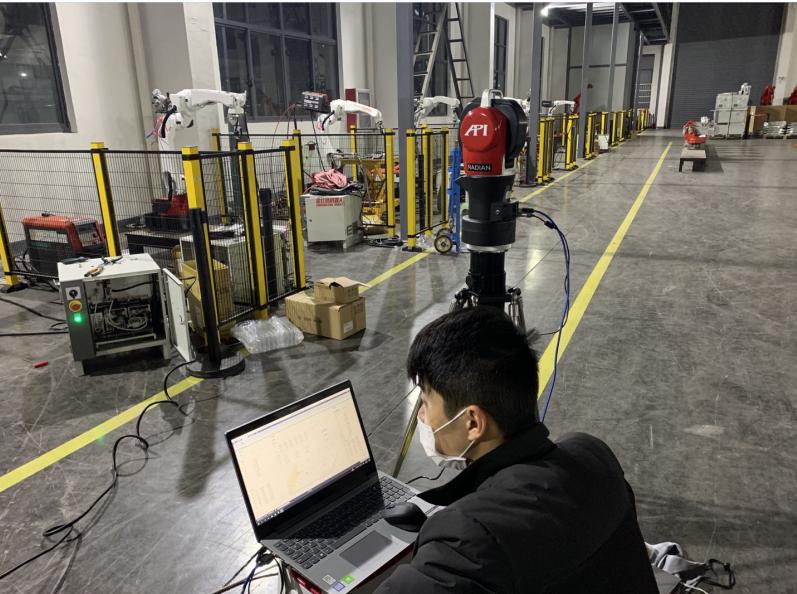

LASER CALIBRATION TEST REPOSITIONING UKUCHANEKA

I-JHY isebenzisa indlela yokulinganisa i-laser ukuvavanya ukuchaneka okuphindaphindiweyo kwerobhothi.Emva kovavanyo oluninzi, ukuchaneka okuphindaphindiweyo kwerobhothi yethu kuphezulu kakhulu kune ± 0.08mm.

SEBENZISA IIBRAND EZINGAPHEZULU ZOKUFIKELELA IZINTO EZINGUNDOQO

Izixhobo ezingundoqo zerobhothi ezifana ne-servo motor, i-RV reducer, i-harmonic reducer, i-servo drive kunye nokunye ukusebenzisa ii-brand zase-China eziphezulu, eziye zavavanywa ngokusetyenziswa kwethu ixesha elide ukuqinisekisa ukuba zifanelekile kwirobhothi yethu.

UKULONDOLOZA OKULULULE

Ugcino lulula, Ngokwesikhokelo solondolozo esibonelelwa sithi abathengi ngokwabo banokusebenza ngokulula.

EMVA KWESALE GUARANTEE

Wonke umthengi uneqela lakhe lenkonzo emva kokuthengisa.Ukuba ufuna naluphi na uncedo emva kwentengiso, Pls buza nangaliphi na ixesha.Iinjineli zethu zobuchwephesha ziya kuyicombulula ngelona xesha lifutshane.Ingongoma kukuba konke simahla.

| I-Welding parameters reference kwintsimbi ethambileyo kunye nentsimbi ephantsi ye-alloy | |||||||||

| uhlobo | ipleyiti | Idayamitha yocingo | umsantsa weengcambu | welding yangoku | umbane welding | isantya welding | Qhagamshelana ingcebiso-workpiece umgama | Ukuhamba kwerhasi | I-engile yokuwelda |

| Ukuwelda kwempundu okwe-T | 1.0 | 0.8 | 2.5~3 | 70 ~ 80 | 17 ~ 18 | 8~10 | 10 | 10~15 | 45° |

| 1.2 | 1.0 | 3-3.5 | 85-90 | 18 ~ 19 | 8~10 | 10 | 10~15 | 45° | |

| 1.6 | 1.0,1.2 | 3-3.5 | 100-110 | 18-19.5 | 8~10 | 10 | 10~15 | 45° | |

| 2.0 | 1.0,1.2 | 3-3.5 | 115-125 | 19.5-20 | 8~10 | 10 | 10~15 | 45° | |

| 2.3 | 1.0,1.2 | 3-3.5 | 130-140 | 19.5-21 | 8~10 | 10 | 10~15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5~4 | 150 ~170 | 21-22 | 7.5~8 | 15 | 15 ~ 20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5~5 | 180-220 | 21-23 | 6.5–7.5 | 15 | 15 ~ 20 | 45° | |

| 1.2 | 5 ~ 5.5 | 200-250 | 24-26 | 6.5~8 | 10~15 | 10~20 | 45° | ||

| 6 | 1.2 | 5 ~ 5.5 | 230-260 | 25 ~ 27 | 6.5–7.5 | 20 | 15 ~ 20 | 45° | |

| 6 | 220-250 | 25 ~ 27 | 5.5–7.5 | 13 ~ 18 | 10~20 | 45° | |||

| 4 ~ 4.5 | 270-300 | 28-31 | 10-11.5 | 13 ~ 18 | 10~20 | 45° | |||

| 8,9 | 1.2,1.6 | 6 ~7 | 270-380 | 29-35 | 6.5–7.5 | 25 | 20 ~ 25 | 50 ° | |

| 8 | 1.2 | 5 ~6 | 270-300 | 28-31 | 9~10 | 13 ~ 18 | 10~20 | 45° | |

| 1.2 | 7; 8 | 260-300 | 26-32 | 4 ~ 5.5 | 15 ~ 20 | 10~20 | 50 ° | ||

| 1.6 | 6.5~7 | 300 ~ 330 | 30-34 | 5 ~ 5.5 | 15 ~ 20 | 10~20 | 50 ° | ||

| 12 | 1.2,1.6 | 7; 8 | 270-380 | 27-35 | 4.5–6.5 | 20 ~ 25 | 20 ~ 25 | 50 ° | |

| 1.2 | 7; 8 | 260-300 | 26-32 | 4 ~ 5.5 | 15 ~ 20 | 10~20 | 50 ° | ||

| 1.6 | 6.5~7 | 300 ~ 330 | 30-34 | 5 ~6 | 15 ~ 20 | 10~20 | 50 ° | ||

Phawula:

1. I-MIG i-welding isebenzisa igesi ye-inert, isetyenziselwa kakhulu i-welding ye-aluminium kunye ne-alloys yayo, ubhedu kunye ne-alloys yayo, i-titanium kunye ne-alloys yayo, kunye nensimbi engenasici kunye nentsimbi ekwazi ukumelana nokushisa.Ukuwelda kwe-MAG kunye ne-CO2 yegesi ekhuselweyo isetyenziselwa ukuwelda intsimbi yekhabhoni kunye nentsimbi esezantsi eyomelele kakhulu.

2. Lo mxholo ungasentla ubhekiselele kuphela, kwaye kungcono ukufumana i-optimal process welding parameters ngokuqinisekiswa kovavanyo.Iidamitha zocingo ezingentla zisekelwe kwiimodeli zangempela.